I had a problem. I wanted to make a Toyota Supra crochet car as a gift for my friend. But between the fake AI patterns and the toy-looking cars I could not find something that would fit my vision.

So I decided to try my hand at making my own pattern. And to help anyone else working from a similar problem I will be posting it for free online. I would appreciate a credit if you do end up making your own car based off this pattern but it's absolutely not required. I simply want to pass it forwards for all the free patterns I've used in the past and share something that others can make as well.

With that, let's get started.

Materials

- 3.5mm crochet hook

- Large sewing needle

- Scissors

- row counter (optional)

- Medium weight yarn (4)

- Blue (Main car body color)

- Dark Grey (underside and windows)

- Black (front and rear grilles, window trim)

- Red (brakes)

- Dark Red (rear lights)

- Light Grey (headlights and side mirror)

- Foam (to hold the shape for the main body of the car)

- Razor (to help cut foam to shape)

- Stuffing

Note: not all of my yarns were from the same brand so some tended to be a

little thicker and you may have to adjust row-counts for some items to

make the pattern work for you.

If you do not have a pile of random yarn colors in your home like I do, feel free to group the Dark and Light suggested colors into a single color.

Stitch Decoder

ch - chain

sl - slip stitch

sc - single crochet

hdc - half double crochet

dc - double crochet

htr - half triple crochet

tr - triple crochet

dec - decrease

Pattern

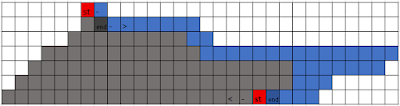

The first thing I did was find some reference images of the car. I set these up in a square excel sheet and colored in the rough shape of the car. This would let me know roughly the correct ratios for heigh, length, etc that I would need to hit for a more realistic looking car.

Main Body

I chose to make a very long panel in order to make the top and bottom section of the car, and then use two side panels for the sides of the car.

Long Panel

1. (grey) ch12, turn

2.-5. sc11, ch1, turn

6. sc11, ch3, turn

7. sc13, ch3, turn

8. sc15, ch3, turn

9. sc17, ch3, turn

10. sc19, ch3, turn

11. sc21, ch3, turn

12.-21. sc23, ch1, turn

22. sc22, ch1, turn

23.-43. sc21, ch1, turn

44. sc20, ch1, turn

45.-61. sc19, ch1, turn

(swap to blue)

62.-86. sc19, ch1, turn

87. sc19, ch2, turn

88. sc20, ch2, turn

89.-108. sc21, ch1, turn

109. sc21, ch2, turn

110. sc22, ch2, turn

111.-120. sc23, ch1, turn

121. sc21, ch1, turn

122. sc19, ch1, turn

123. sc17, ch1, turn

124. sc15, ch1, turn

125. sc13, ch1, turn

126. sc11, ch1, turn

127. sc11, ch1, turn, sc around the edge and end around row 6. Start a new edge sc on opposide side to go around the rest of the project.

Due to how I do the panel increase and decreasing this does result in a slightly uneven pattern. I used the edge stitching to even it out a little bit by adding some hdc or thicker stitches around the shorter edges. The final product doesn't end up looking too bad despite this unevenness.

Side Panel (x2)

1. (blue) ch57, turn

2. sc56, ch3, turn

3. sc58, turn

4. (first sl in second sc) sl6, sc51, ch1, turn

5. sc49, turn

6. sl2, sc46, ch1, turn

7. sc45, turn

8. sl3, sc41, sc around edge, end

Make two and flip one over for the other side.

Stitching

I chose to start my stitching by connecting the large main panel together by it's front nose. Then I stitched the bottom sections of both side panels onto the bottom of the main panel. From there I started counting stitches to make sure that I could stitch this panel evenly on both sides.

I stitched some more to close up the body further and then I got myself a piece of foam to cut to shape. I forgot to take a photo but I pretty much just carved the foam to look like the body shape I wanted it to and then stuffed it into the body to check fit. As a tip, cut larger than you think you need to as you can always cut more material off but it's a pain to try to put pieces back together.

Once you have a shape you like you can close up the rest of the stitching.

Windows and Roof

Top Window Section and Spoiler

1. (grey) ch10, turn

2. sc9, ch2, turn

3. sc10, ch2, turn

4. sc11, ch2, turn

5. sc12, ch2, turn

6.-7. sc13, ch1, turn

8. sc13, ch2, turn

9. sc14, ch2, turn

10.-12. sc15, ch1, turn

(swap to blue)

13.-27. sc15, ch1, turn

28. sc15, ch2, turn

(swap to grey, do not cut blue yarn off, you will use it to sc around and make the spoiler; described in next section)

29.-35. sc17, ch1, turn

36. sc16, ch1, turn

37. sc14, ch1, turn

38. sc13, ch1, turn, sc around front window (pull thread through the stitching across the top of the window to get to the other side and finish it)

Spoiler

Use the blue yarn you stitched the roof of the car with to sc around the edge until you reach the back of the rear window.

1. sc10 across back window, ch5, turn

2. sc, inc, sc, inc, sc10, ch5, turn

3. sc, inc, sc, inc, sc, hdc2, dc4, hdc2, sc2, sl3, turn

4. sl2, sc2, hdc2, dc4, hdc2, sc2, sl3, turn

5. (all in back loop) sl, sc3, hdc2, dc4, hdc2, sc3, sl, turn

6. sl2, sc, hdc2, dc4, hdc2, sc, sl3, close sl, sew inside back to the other edge to close up the spoiler and sc the rest of the blue edge

Side Windows (x2)

Window Piece

1. (grey) ch21, turn

2. sl, sc19, ch3, turn

3. sc20, turn

4. sl, sc10, sl2, turn

5. sl, sc9, turn

6. sl, sc, sl, end

For the next part, you will be starting your stitching in the top of the grey window. Start from the first sl you made in row 6 by pulling your blue thread through and hdc into the next loop (the sc in row 6). You might need to go by eye on this next section to make it look better for yourself.

Window Edge

1. (blue, start from first sl in row 6) hdc, sc2, hdc to end of grey (~12hdc), ch9, turn

2. sl, sc4, hdc2, sc3 (into the grey), turn

3. sl, sc, hdc, sc, sl, end

Stitching

Lay out all of your window pieces next to each other, Then stitch with grey thread the front of the window and the grey exposed sides of the window together. Use blue thread for the blue edges. This should already start shaping properly to what you want the top of the car to look like.

Next, line up the top section with the body of the car you made before. Make sure the spoiler is appropriately aligned with the back of the car and the rest of the window panels are roughly even. Then stitch together. I started stitching back to front using blue thread.

Fill the top section with stuffing, or foam if you want a more shaped look. I used stuffing so the top section looks a bit less shaped and more rounded.

Wheels and Wheel Well

My main goal for the wheels was to make sure they wouldn't be sticking out super far as a lot of the car design's I'd seen, so I focused on making a circle, and only the depth necessary for it to stick out a little with some extra material at the bottom to indicate that the tire would be a normal thickness underneath.

Front Wheels (x2)

If you want to add the red brake calipers seen in the photo, I have added the sc numbers where you will need to swap from black stitching to red (front left and front right wheels have mirrored setups).

1. (grey) 6sc in magic circle

2. (black) inc around (12) *For brakes, use red in sc 2-4 (FL) or 8-10 (FR)

3. (sc, inc) repeat around (18) *For brakes, use red in sc 2-7 (FL) or 11-16 (FR)

4. (grey) (2sc, inc) repeat around (24) *for circle smoothness use grey only in the top loop for the first 2sc, then swap to fully using grey

5. (black) (3sc, inc) repeat around (30) *for circle smoothness, use grey in the loop pull through for the first 2sc, then swap fully to black

6. 3sc normal, rest sc only in back loop (30)

7. 3sc back loop, sc, ch, turn

8.-12. 10sc, ch, turn (10)

13. (in back loop only) dec, sc2, dec, sc2, dec, ch, turn (7)

14. dec, sc3, dec, end (5)

Rear Wheels (x2)

Pattern follows the same ideas as above.

1. (grey) 6sc in magic circle

2. (black) inc around (12) *For brakes, use red in sc 2-4 (FL) or 8-10 (FR)

3. (sc, inc) repeat around (18) *For brakes, use red in sc 2-7 (FL) or 11-16 (FR)

4.

(grey) (2sc, inc) repeat around (24) *for circle smoothness use grey

only in the top loop for the first 2sc, then swap to fully using grey

5. (black) (3sc, inc) repeat around (30) *for circle smoothness, use grey

in the loop pull through for the first 2sc, then swap fully to black

6. 3sc normal, rest sc back loop (30)

7. 3sc back loop, sc around (30)

8. sc around (30)

9. sc5, ch turn

10.-12. 10sc, ch, turn (10)

13. (in back loop only) dec, sc2, dec, sc2, dec, ch, turn (7)

14. dec, sc3, dec, end (5)

You can also take the time now to stitch on the wheel spokes. I used some grey thread to make 10 spokes around the circle.

Fender (x2)

The back of the car widens slightly. This is where having the narrower back end of the car pays off, as I can create this widening look now with some extra crocheting around the rear wheels that stick out a bit more. One thing to note is that you need to make sure to mirror the front and back loop stitching steps for your second fender so the pieces will be mirrored on either side of the car properly.

1. (grey) ch51, turn

2. sc 50, ch, turn

3. (blue) sc 50, ch24, turn (73)

4. sc 22 in back loop, sc 1 normal, sc25 in back loop, sc25 normal, ch1 turn (73) *front loop for second

5. sc 21 in front loop, dec, sc, dec 2, sc9, sl2, turn (34) *back loop for second

6. sl in first sl, sc6, hdc2, dec hdc 2, sc2, inc, sc2, inc, sc2, inc, sc2, hdc inc, dc inc, htrc and hdc in same, sc, inc, sc2, inc, sc3, ch1, turn (37)

7. sc5 front loop, sc, hdc, hdc inc, htr, htr and tr and htr in same sc, hdc and sc in same sc, sc, sc 10 in front loop, sc 2 normal, inc, hdc 2, dec dc 2, dec hdc, sc, sl2, turn (38) *back loop for second

8. sl in first sl, sc 4 in back loop, hdc 2 back loop, hdc inc back loop, sc 2 back loop, sc 12 normal, sc 2 back loop, inc back loop, hdc and sc back loop, sc 3 back loop, sl, end (43) *front loop for second

Stitching

Start by pinning all of the wheels to the car to figure out your placement. Based off the fender length, you want the front and rear wheels to be separated by about 5 1/2". I used black thread to stitch all of the wheels to the car, use stuffing to fill out the wheels.

Next will be stitching the edge onto the car. Start by pinning the fender piece to the side of the car to measure out how it will look, then use grey thread to stitch the grey lower section to the underside of the car, and blue thread to stitch the top pieces. Use stuffing to fill out the rear section of the fender.

Front Grille

Now we're getting into the smaller details of the car. From here on out I will not be separating the stitching step as a lot of these steps will involve crocheting the pieces and then stitching them on one after another. I find this is easier as it'll be easier to judge if any of these smaller pieces need to be altered to fit better.

Front Grille

I decided that dark grey would not look as nice for the front of the car so I make a wider black grille to cover the front of the car.

1. ch5, turn

2. sc2, sl, turn

3. sl into sc, hdc, ch2, turn

4. hdc, sc2, hdc and sc into original ch, ch32, turn

5. sc2, sl, turn

6. sl into sc, hdc, ch2, turn

7. hdc, sc2, hdc and sc into next ch, sl2 back loop, sc3, hdc17, sc3, sl1, turn to other side of ch

8. sc23 in front row, ch2, turn

9. sc24, ch, turn

10. sc24, turn

11. sc22, sl, end

This photo is from roughly row 7, before the flat middle section is built up.

Blue Edge (sc on either side of the Front Grille)

Next you will want to start stitching some blue edge pieces in the triangles you built for the above piece.

1. (blue) sc4, sl2, turn

2. sl, sc2, hdc2, ch4, turn

3. sc2, hdc, sc, sl2, turn

4. sl5, sc4, hdc2, sc3, end

I stitched this piece to the front of the car, pinning the piece roughly so it would be in the middle. Black thread for the black pieces and blue thread for the blue. The two side pieces ended up reaching all the way to the fender line and I roughly stitched them into and around the fender so it rounded out the wheel area a bit more.

Note that the first row of black hdc stitches made (row 7) before stitching the rest of the square section on the other side of the chain is meant to be a small lip. That row doesn't get stitched down but rather one row inwards roughly where the chain originally was.

Blue Grille Lines

A couple pieces making up the blue lines shaping the front of the car.

Center Line

1. ch31, turn

2. sc30 back, end

The center vents are stitched from the bottom edges of the black area, up along the red marker and then down again to finish on the other side. To show off the raised edge, only stitch from one of the edges, not flat from the center.

Side Vents (x2)

1. ch13, turn

2. sc12, turn

3. sc in second sc, sc4, ch1, turn

4.-5. sc4, ch1, turn

6. sl1, sc3, end

I added some extra black stitching along the side before I installed the side vents as I felt like I didn't have enough.

The side vents get sewn along the side of the car as shown below.

Front Headlights (x2)

1. (light grey) ch11, turn

2. sl3, sc2, hdc5, ch3, turn

3. sc7, sl2, end

The headlights are stitched just above the side vent detailing, roughly parallel with the two black vents on the sides.

And that's it for the front of the car!

Rear

The rear section has a couple parts to it as well. I started off very simple and then very quickly ended up adding the black rear coloration again for looks and some exhaust pipes.

Rear Headlights

1. (dark red) ch10, turn

2. in back, sl, sc6, hdc2, ch2, turn

3. hdc, sc3, sl3, end

Blue Outline Edge

1. (blue) ch30, end

These were the first two pieces I made for the rear. Just a blue string to outline the rear a little better that I stitched in. And then two headlights stitched near the top and slightly curving around to the sides ending before the blue fender we stitched earlier.

Rear Backpiece

1. (black) ch20, turn

2. hdc19, ch1, turn

3. in back loop, sc, (red) hdc5, (black) sc7, (red) hdc5, sc1, ch2, turn

4. sc20, ch2, turn

5. sc21, ch2, turn

6. sc22, ch5, turn

7. sc, hdc, dc, sc1 into dc side, sc1 into dc sc, sc23, ch5, turn

8. sc, hdc, dc, sc1 into dc side, sc1 into dc sc, sc2, sl, end

The top 2 rows again are meant to be a small lip that sticks out from the car so when you stitch the back piece on make sure you don't stitch rows 1-2 down. The lower section of the car will go slightly under the underside of the car and the small triangles come up behind the wheel fender.

Rear Backpiece Edge Extension

1. (black) ch5, turn

2. in back, sl, sc6, hdc2, ch2, turn

3. hdc, sc3, sl3, end

This edge is to add a little bit of black material that sticks out from the rear of the car. You can sew it just along the edges of the main black rear piece. You want to try to make a square shape for the back and close the top along where the top lip starts.

Exhaust

1. (grey) mr6 (or ch1 and sc6 into the ch)

2.-3. sc6, end

Super simple exhaust, just two tiny tubes that you will stitch to the back of the car.

Window Trim and Mirrors

The final detail I added to enhance the car was some black window trim and side mirrors.

Rear Window Trim

1. (black) ch56, turn

2. sc 3, dec3, hdc dec, hdc 11, hdc dec, dec3, sc5, dec3, sc5, dec3, sc2, end

Stitch around the rear window.

Front and Side Windows

Main Window Triangle (x2)

1. (black) ch11, turn

2. in back, sc2, hdc3, ch1, turn

3. sc2, sl, turn

4. sl in second sc, inc, ch18, end

Side Window Triangle (x2)

1. (black) ch20, turn

2. in back, sc2, hdc2, dc, ch1, end

Front Window Trim (x2)

1. (black) ch17, end

Start with the larger triangle and stitch the two larger triangles onto the edges of the car.

The smaller triangles will be set up in the back and the long chain used for the top side window trim. The final front window trim will just be stitched to the top and bottom of the front window.

Side Mirrors

Side Mirror (x2)

1. (black) ch6, turn

2. sc2, hdc3, ch1, turn

3. hdc3, clip and start sc into one side (other mirror other side) sc8 in a circle sl end in starting sc

Mirror (x2)

1. (light grey) ch3, turn

2. hdc2, end

Stitch the mirror into the empty gap of the side mirror piece above.

These mirrors will then be stitched into the large triangle piece. There is no need for wires to hold them up as the arms are relatively short and you should be able to shape the stitching to hold up the side mirrors.

Done!

Final Thoughts

And with that the car is completed! There are parts that I wish I did a little better (namely sewing the tires on a bit more evenly) but I am happy with how it turned out. It's the first custom pattern I've made in a while and the first I've ever shared. I'm tempted to maybe make a pattern for my NC miata next.

I would love to see your own builds if you do end up using this pattern to make your own!